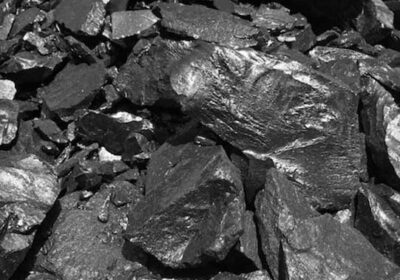

Asian Gilsonite is one of the main manufacturer and supplier of Gilsonite powder Foundry grade with good conditoin and high quality packing for exporting to other countries.

Gilsonite is used as a carbonate additive in casting sand, which creates smoother plates on gray iron molds. Gilsonite is mixed with the coal formed in the ocean crust and is used as a special adhesive for casting sand, which reduces the defects at the end of the casting process. Gilsonite is also used in foundry as a binder for shaping metals and mixing with chemical compounds such as magnesium and hydrated lime for desulfurization in steel industries. Gilsonite additive in molding and casting sand acts as a resin and creates adhesion between sand and other materials. After filling the mold, this adhesion helps that the gas emitted from the sublimation of Gilsonite causes pressure on the poured material and it is easier. The mold should be separated from the cast material. At the same time, the surface of the mold remains very smooth.

Gilsonite, also known as natural bitumen, is a naturally occurring solid hydrocarbon used in various industrial applications, including in foundry operations. Here’s how it is utilized in foundries:

1. Molding Sand Additive:

Function: In foundries, Gilsonite is added to green sand mixtures used for making molds. It acts as a carbonaceous additive, improving the sand’s properties.

Benefits:

Improved Surface Finish: The carbon content in gilsonite creates a reducing atmosphere during metal pouring, which helps prevent oxidation of the metal and results in a smoother surface finish on castings.

Enhanced Collapsibility: Gilsonite helps make the sand mold easier to break apart after casting, reducing the need for extensive cleaning.

Strength and Flowability: It improves the strength and flowability of the sand mixture, ensuring better molding quality.

2. Reduction of Defects:

Minimizes Gas Defects: Gilsonite has a high volatile content that helps control gas evolution during metal pouring, thus reducing the risk of gas-related defects in the castings.

Control of Expansion Defects: The presence of gilsonite helps in controlling expansion defects, which can occur due to the thermal expansion of the sand.

3. Binder Properties:

When heated, gilsonite melts and acts as a binder, which helps to hold the sand grains together during the molding process. This temporary binding property improves the dimensional stability of the mold during metal pouring.

4. Usage and Proportion:

Gilsonite is typically added in specific proportions, often ranging from 2% to 5% by weight, depending on the requirements of the casting and the type of metal being cast.

5. Types of Castings:

It is commonly used for gray iron and ductile iron castings due to its excellent performance in creating a reducing atmosphere, which is beneficial for these types of metals.

Contact with Asian Gilsonite sales team for Gilsonite use able in foundry by email or WhatsApp.

WhatsApp: http://wa.me/+971569584522

Overview

Features:

- Gilsonite for foundry

- Foundry

- Casting

- Molding

Leave feedback about this