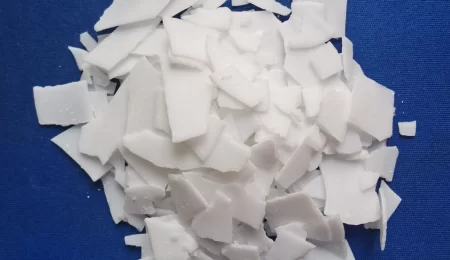

Polyethylene wax (PE wax) is a low molecular weight polyethylene polymer widely used across various industries due to its unique properties such as low viscosity, high melting point, hardness, and thermal stability. Here are some of the key applications of PE wax:

- Plastics Industry

Lubricants: PE wax acts as an external lubricant in the processing of PVC and other plastics, reducing friction during extrusion and injection molding, which improves the surface quality of the final product.

Dispersing Agents: It helps in the uniform dispersion of fillers and pigments in the plastic matrix, enhancing the color consistency and mechanical properties. - Rubber Industry

Processing Aids: PE wax is used as a processing aid in the rubber industry to improve the flow and mold release of rubber compounds.

Anti-blocking Agent: It prevents rubber sheets from sticking together during processing and storage. - Adhesives and Coatings

Hot Melt Adhesives: PE wax improves the thermal stability and set time of hot melt adhesives, making them more efficient and durable.

Coatings: It provides scratch resistance, gloss control, and slip properties in various coatings, including paints, varnishes, and printing inks. - Textile Industry

Softening Agent: PE wax is used in textile treatments to impart a soft and smooth feel to fabrics.

Water Repellency: It can be used to enhance the water repellency of textile products. - Cosmetics and Personal Care

Thickening Agent: In cosmetics, PE wax acts as a thickener and stabilizer in formulations such as lipsticks, creams, and lotions.

Film Former: It provides a protective film and improves the texture and wear resistance of cosmetic products. - Paper and Packaging

Coatings: PE wax is used in paper coatings to provide water resistance, gloss, and smoothness to packaging materials.

Emulsions: It is used in wax emulsions for paper and cardboard to enhance their strength and printability. - Candles

Hardness and Gloss: PE wax is blended with paraffin wax to increase the hardness and gloss of candles, resulting in a better appearance and longer burn time. - Road Marking Paints

Durability: It enhances the durability and wear resistance of road marking paints, ensuring that they remain visible for longer periods under harsh conditions. - Metalworking

Lubricants and Release Agents: In metalworking, PE wax serves as a lubricant and release agent, reducing friction and wear on tools and molds. - Masterbatches

Carrier for Additives: PE wax applications is used as a carrier for additives in masterbatches, ensuring uniform distribution and easy processing of colorants, UV stabilizers, and other additives in polymer matrices.

Leave a Reply